Editorial

How The G-SHOCK Premium Line Elevates Functionality with Japanese Soul

How The G-SHOCK Premium Line Elevates Functionality with Japanese Soul

For over four decades, the Casio G-SHOCK has been synonymous with durability, functionality, and an unmistakable spirit of innovation. Known globally for its tough-as-nails exterior and military-grade resistance, the reputation of G-SHOCK has long been cemented as a symbol of ruggedness. However, beneath this rugged image lies an evolution that many may have overlooked — that while every model is crafted with machine-like precision, there’s a soul embedded within — a tribute to the artisans and engineers who dedicate themselves to creating watches that are as much a work of art as they are a technological feat.

Defining the Japanese identity for the G-SHOCK brand

The G-SHOCK Premium line represents the pinnacle of the Casio brand’s watchmaking abilities. While the standard G-SHOCK models are widely loved for their durability and affordability, the premium models are designed to showcase the brand’s attention to detail. These timepieces marry advanced materials like titanium, carbon fiber, and sapphire crystal with innovative horological features like GPS, solar power, and Bluetooth connectivity, all while maintaining the watch’s iconic resistance to shock and water.

This juxtaposition of materials, innovation, and craftsmanship sets the G-SHOCK Premium line apart. From the MRG series, which features titanium cases hand-finished using traditional Japanese polishing techniques, to the MT-G collection that boasts a hybrid construction combining stainless steel and reinforced resin, Casio has created a line of timepieces that not only perform flawlessly but also appeal to the discerning collector. And yet, despite their industrial precision, these watches exude a soulfulness deeply rooted in Japanese culture.

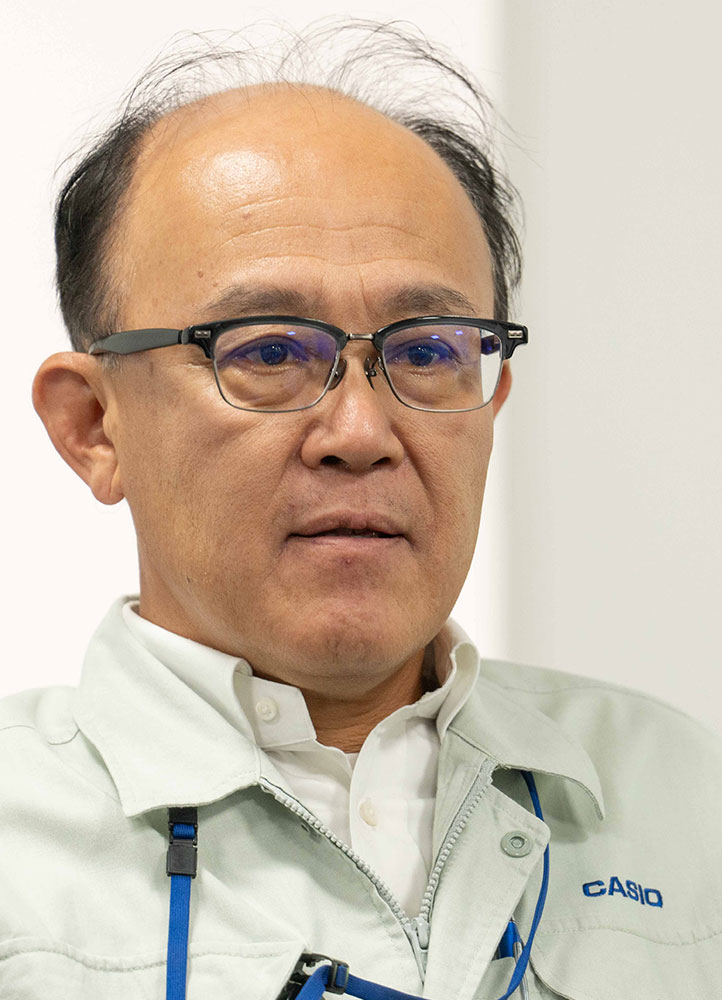

To understand the true essence of the G-SHOCK Premium Line, one must look at the broader context of Japanese craftsmanship, or monozukuri. This term refers to a philosophy of manufacturing that emphasizes craftsmanship, quality, and continuous improvement — a deeply ingrained value in Japanese industries. “It’s not wrong to say that watches with digital functions, namely Garmin and Apple, are our market competitors when it comes to watch functionality in that category,” said Mr. Oh Takahashi, Senior General Manager of Casio Timepiece Business Unit.

“But I don’t think that when it comes to wristwatches, function is the only thing that people are looking for — it has to be about making something that people want to continue to use. Instead of merely looking for a watch, it’s “they’re looking for a G-SHOCK” is what we want people to say. That’s why we want these watches to look cool, to want to be seen with them. Being attracted to the brand name is a unique position that we want to solidify. We want to be a cool brand. And if we can maintain that image, if we build in the functions that are useful and not just functions for function’s sake, then we’ve hit all the right spots.”

The soul of G-SHOCK is more than of mere machine

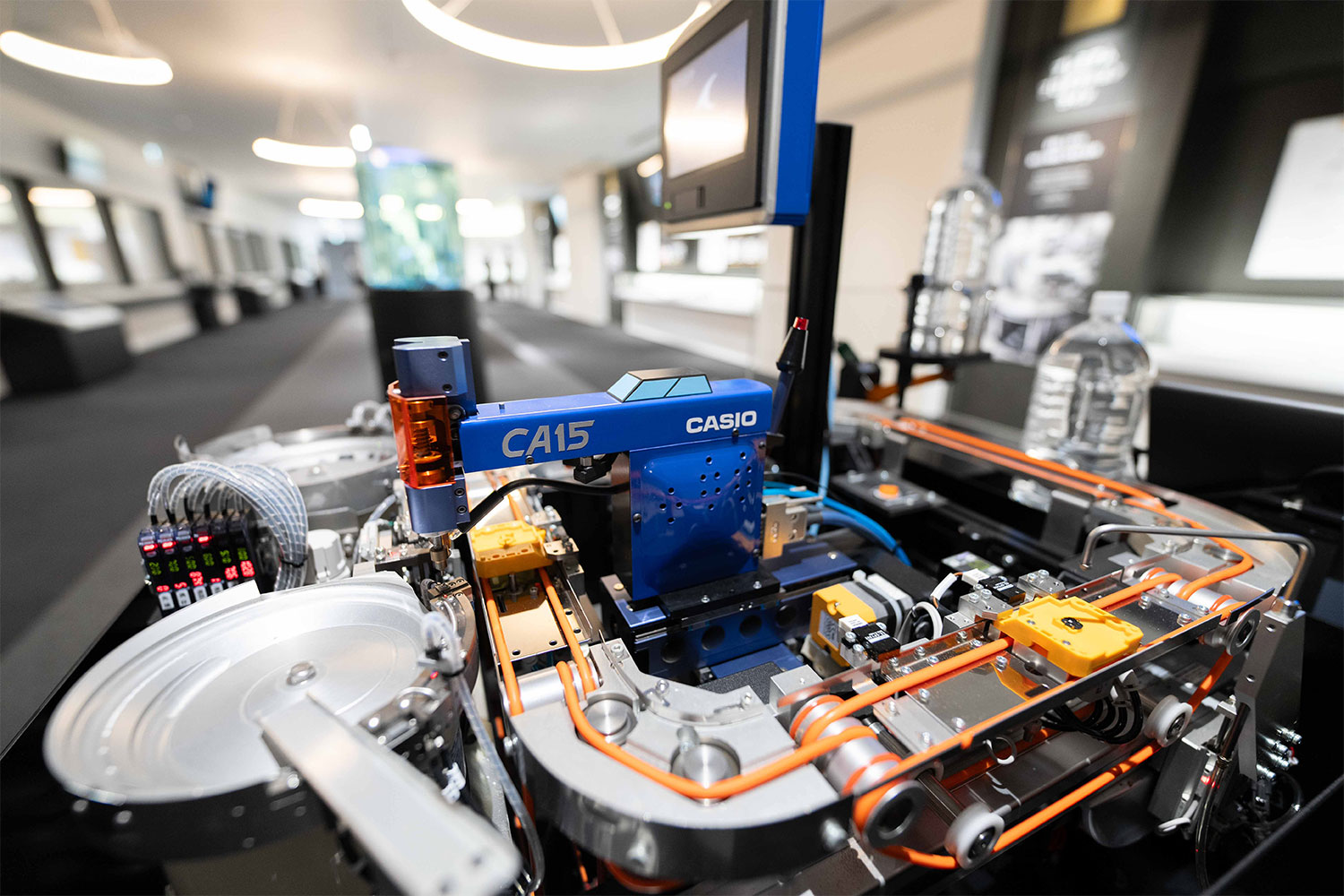

The very nature of the Casio manufacturing process can make it easy to assume that G-SHOCKs are mechanical marvels devoid of emotion — products of relentless, efficient engineering. Sure, these watches are produced in high-tech facilities that operate like well-oiled machines. Robots precisely cut moulds, mass machines (that Casio built in-house) churn out a multitude of microscopic gears and rotors, thereafter apply coatings and assemble components with the exactitude of Swiss watchmaking giants. Yet behind each G-SHOCK are individuals who imbue the product with a sense of purpose. This is especially evident in the Yamagata Manufacture, a site area of 82,547 sqm housing nine departments, where the production line of G-SHOCK premium timepieces all happen along a G-shaped production belt. Assembly and final inspections all happen here, before being packed and delivered off to inventory.

The G-SHOCK Full Metal series, whose case components are made in Dongguan, China, before its final assembly in the Yamagata factory, begin an arduous phase to completion, one of which includes its meticulous assembly of watch hands. It’s a part that I’ve seen demonstrated a number of times before, although in the traditional watchmaking fashion of securing perfect placement of stacked hands at ‘12’ as the watchmaker stares intently through a loupe, with his body hunched over his bench. That’s not to say that G-SHOCK found an easy way to do this — it is still a very calculated assembly, but comprising a set-up that’s aided with visual monitors and its pre-programed guidelines showing X-, Y-, and Z-axes, that failure to adhere to the station’s own inspections simply will not pass the watch through to the next.

In other words, the Casio engineers and technicians who design and build the G-SHOCK Premium Line aren’t just concerned with meeting technical specifications; it is important that each technician understands that each watch that passes through their hands are not just products of modern mass production, but of takumi — in Japanese to mean craftsmanship and excellence. Only “Medalists” are allowed to work on the Premium Production Line. To qualify, technicians must undergo a series of strict skill certifications that runs according to grade (bronze to platinum) before reaching the covetous title of “Meister”. According to Mr. Shinichi Kimura, President & CEO of Yamagata Casio Co., it’s possible to accrue just 0.095% of passes out of 40,000 applicants — currently only one Meister is qualified on-site.

“When we try to maintain and improve the quality in manufacturing, the promise of “Made in Japan” is to make sure that what comes out of Yamagata is high-quality and sophisticated,” said Mr. Kimura on the importance of the made-in-Yamagata identity. “We want to have new talents to give us ideas that come from new kinds of knowledge. Perhaps it’s something technology-oriented that’s peppered with artificial intelligence or IOT-related (internet of things) to advance our production lines. We absolutely want to be cutting-edge.”

In limited-release models such as the MRG-B2000B-1A “Kachi-Iro”, inspired by the deep blue hues of Samurai armor, or the MRG-B2000BS-3A “Hana-Basara”, which draws from ancient Japanese weaponry, demonstrate how Casio has mastered the delicate balance between form and function. These watches tell stories, honoring traditions while standing as symbols of modern-day craftsmanship.

Discover the Casio G-SHOCK MRG series here.

With a commitment to evolving the brand’s technological capabilities, the premium G-SHOCK watches appeal to a growing audience of collectors who demand more than just durability, but of timepieces that speak to personal values of innovation, heritage, and emotional connection. “What we’ve been doing is working with anime and game developers and creators, to reach out to an audience who are not necessarily in this top bracket of G-SHOCK premium collectors,” said Mr. Takahashi on the future-proofing of the next generation of G-SHOCK.

“One of our online communities (managed by an administrator from the in-house communications team) is curated on Discord, a gaming community channel — and that’s made up largely of Gen Alphas and Gen Zs. Now, they don’t currently integrate with our current G-SHOCK clientele. To clarify, they are participants on the platform, but they don’t necessarily know what the brand is. But having examined how such a community can evolve and grow, we’re expecting that community to reach 1 billion in about five years. At that time, we know that the impact within that G-SHOCK community will have definitive growth at that stage.”

Casio G-Shock