Interviews

The World’s Toughest Watch Gets an Artisanal Japanese Touch

The World’s Toughest Watch Gets an Artisanal Japanese Touch

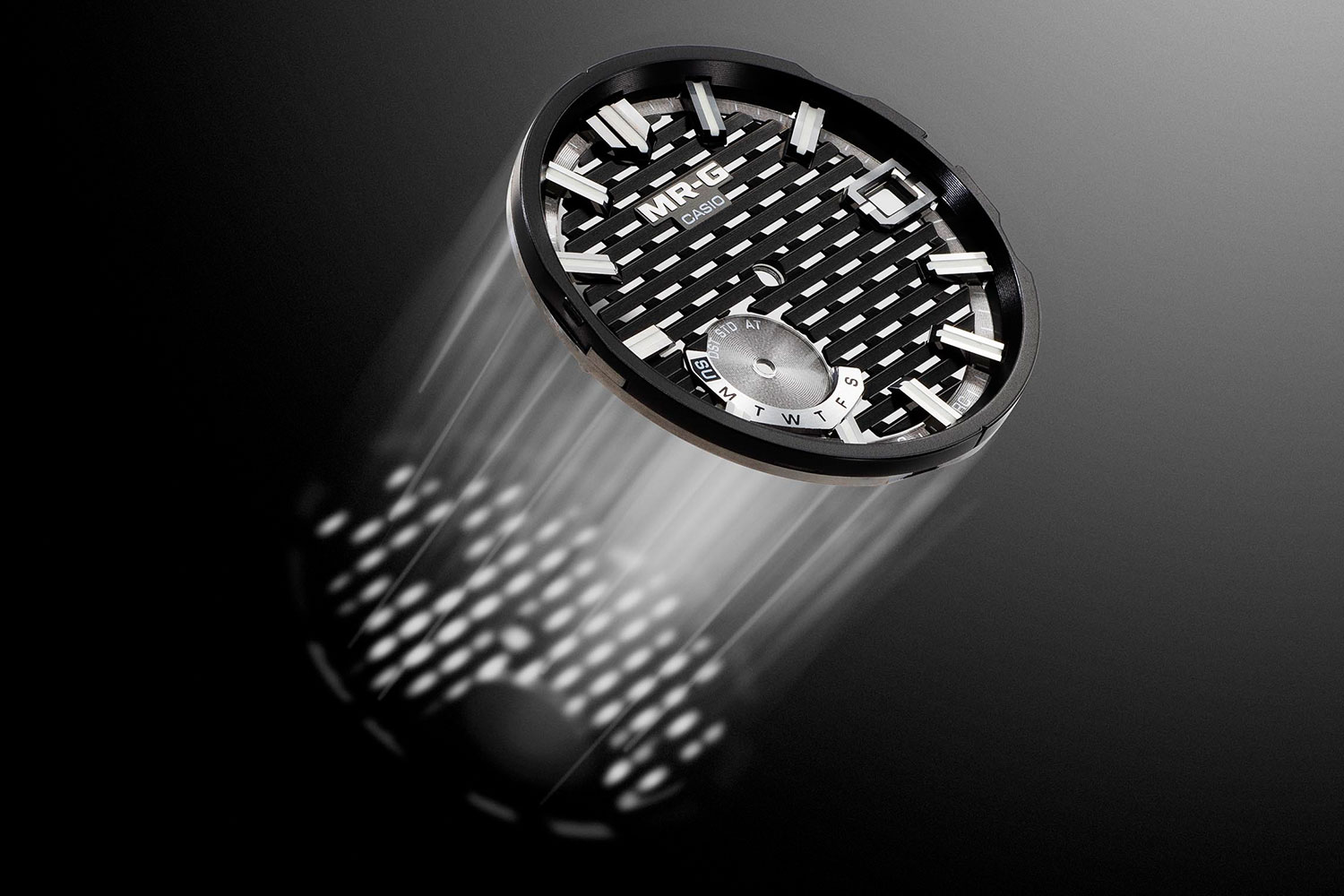

Casio has unveiled a new addition to its G-SHOCK 2100 line, elevating the collection to the esteemed MR-G series. Outfitted in glistening black metal, the latest MRG-B2100B model combines the iconic style and comfortable fit of the 2100 line with the sophistication and durability characteristic of the MR-G name.

View this post on Instagram

These are exhibited in two main features. Firstly, the meticulous polishing of the multi-component structure that was done prior to assembly — down every nook, crevice, edge and all. Secondly, a dial design that draws inspiration from “kigumi”, the traditional Japanese art of interlocking woodwork, reflecting a deep appreciation for Japanese aesthetics and artisanal skills.

G-SHOCK: From function to form

The evolution of Casio’s G-SHOCK from a rugged, utilitarian watch to a premium timepiece is a fascinating journey of innovation and resilience. When Casio introduced the first G-SHOCK in 1983, it was designed to be virtually indestructible. Engineer Kikuo Ibe’s vision was to create a watch that could withstand shocks, vibrations, and water — a goal realized with the DW-5000C model. This initial offering featured a robust case and a unique triple-protection design for the components, making it a favorite among those needing a tough, reliable watch.

Over the decades, the G-SHOCK line expanded with a variety of models catering to different tastes and functionalities, from military and sports to fashion and limited-edition collaborations. The watch’s reputation for durability and innovative features, such as solar power, radio-controlled accuracy, and Bluetooth connectivity, solidified its status as a practical yet stylish choice.

In recent years, Casio has elevated the G-SHOCK to new heights with the introduction of the MR-G and MT-G series, blending luxury with the brand’s signature toughness. These premium models feature high-end materials such as titanium, sapphire crystal, and carbon fiber, along with advanced technological features. The MR-G series, for instance, showcases intricate craftsmanship and meticulous attention to detail, positioning it alongside luxury Swiss brands.

In conversation with: Shingo Ishizaka, Product Planning Department

The new MR-G is slated to launch in Singapore tomorrow, but Ishizaka tells me that they’ve gone ahead with its public release in Japan, and it was met with much fanfare. “Obviously, there are lots of G-SHOCK fans who have purchased it, but notably there are also new fans who are looking at MR-G for the first time,” he said.

“People who weren’t familiar with MR-G were drawn in by the watch’s size and the simple design. So going forward, we would like to consider the options that will help us cater our watches to a wider audience.”

As head of MR-G’s range of products, Shingo Ishizaka has been the MR-G Product Planner at Casio since joining the company in 1982. His notable contributions include designing the first FROGMAN model (DW-6300) in 1993, along with creating the iconic diving frog logo on the back of FROGMAN watches. After which, Ishizaka transitioned to the watch product planning department, where he continues to influence Casio’s timepiece development. Currently, his primary focus is on the MR-G models, blending traditional Japanese craftsmanship with cutting-edge technology to create premium, high-performance watches.

You described that the construction of the MRG-B2100B-1A was based on the slim profile of the 2100 series. How do you weigh the importance between aesthetics and functionality, while also making the watch wearable?

Between this MRG-B2100B and the original MRG-B2000 model, the dimensions have been reduced by 5mm across the diameter, and is down 3mm in thickness. This has resulted in a reduced weight of about 30g.

This timepiece however started out structurally-inspired, per se. We worked around the structure of the timepiece that thereafter led to the design elements. Another key part is its thinness; we actually bought in various technologies and skills so that we can make it thinner as much as possible. Though with that said, that feature isn’t necessarily a priority for us at the moment. Across the MR-G series, the models have been increasing over the years, ranging from robust tool watches to simple time-only. Such a range speaks to different kinds of customers. Ideally, we’re looking into what’s required or preferred in the market.

How did the conceptualization for COBARION come about and what were the prerequisites for creating a material of such demand?

We were very intentional in our search for this very hard material. We wanted an exterior that boasts both strength and beauty. From our research, we ended up with COBARION, a cobalt-chromium alloy manufactured exclusively by Eiwa Corporation, and the DAT55G, a titanium alloy manufactured by Daido Steel Co., Ltd. — all proudly developed in Japan.

COBARION, which is used in the top bezel, offers a characteristic that’s four times the hardness of pure titanium, but it also shows off a brilliant gleam when it’s beautifully finished. DAT55G is used in the bracelet links that provides a hardness three times that of pure titanium. On the case, Ti64 is a titanium alloy that has excellent strength and high corrosion resistance. All these hard metals are then finished with a DLC coating for added strength and scratch resistance.

While we’re not developing any proprietary materials, utilizing these extremely hard metals have been fitting for our MR-G watches. In fact, the watch I have on is the MRG-G2000CB-1A that’s fitted with the COBARION bezel and I’ve been wearing it for five years now. People are surprised when they see it in person because its scratch-proof surface and polished finish keeps it looking brand new.

The octagonal bezel is made up of 27 separate components. Based on their different shapes, how important is the integrity of the octagonal construction in order to adapt the dimensions?

The skeleton of this multi-component structure is dependent on the shock-absorbent layers within these small parts. As with any MR-G model, the watch is still equipped with digital functions such as Bluetooth and radio controls.

The incorporation of the kigumi-inspired dial has a lot of symbolism here. I understand it’s specifically inspired by the kumimono-style of bracketing, without the use of nails or screws. On a smaller scale, can you expand on the “high-precision processing technologies” involved in the lattice work?

The lattice work requires much precision. There are lots of small holes as you can see, but despite using plastic resin for the dial, it is actually challenging to keep those holes consistent. Metal dials are heavy, which is a disadvantage in terms of shock resistance. Therefore, we prioritized weight reduction and used plastic materials, but if we used normal manufacturing methods, they would be distorted or the holes would be deformed.

Granted that we are equipped with the right technology and advanced skills to do so, we were able to create a uniform design without the distortion. The lattice design made sense for the solar-powered watch as it allowed light to come through and power the solar cell within.

In the same vein, meticulous finishings for each separate component speaks volumes of the watch — in that it is not just a rugged, shock-resistant timepiece, but one of the highest quality with traditional aesthetics. Will we be seeing more of these integrations in future models?

Yes. We are proud that MR-G is a Made in Japan product manufactured in Yamagata Casio and we would like to consider other technologies, skills or craftsmanship unique to Japan that we can build into the watch going forward.

Our clients have also expressed interest in MR-G timepieces with more minimalistic dial displays such as the MRG-B2100B with an all-analog display. We played around with the idea of three-hand versions but it would be too simple. Instead, we thought more about bringing out the uniqueness of our designs. Now that we’ve conceptualized this kigumi-inspired dial, we’re exploring similar design complexities as opposed to jumping in with functionalities and whatnot, but also with beauty and simplicity.

The G-SHOCK MRG-B2100B-1A launches in Singapore on 30 June 2024 and will be available for purchase exclusively for CASIO-ID members at G-SHOCK ION, MBS, VivoCity, Bugis and Jewel stores. Explore the new launch here.

Casio G-Shock